My searching hasn’t turned up much for the 1940’s era. The one patent I found through a reference from a more recent patent is #2243256. This patent applies to a formed metal shingle. Built into the face of the shingle are several raised bumps. These bumps were likely inserted to stiffen the product and minimize damage during transportation and handling.

I’m actually a little surprised that this patent was awarded. There are many examples of stamped metal shingles with surface features and locking seams that predate this patent. The one that comes to mind initially was made by, and is still available from, the W.F. Norman Company in the mid-West. I suppose that my surprise is not founded in patent fact.

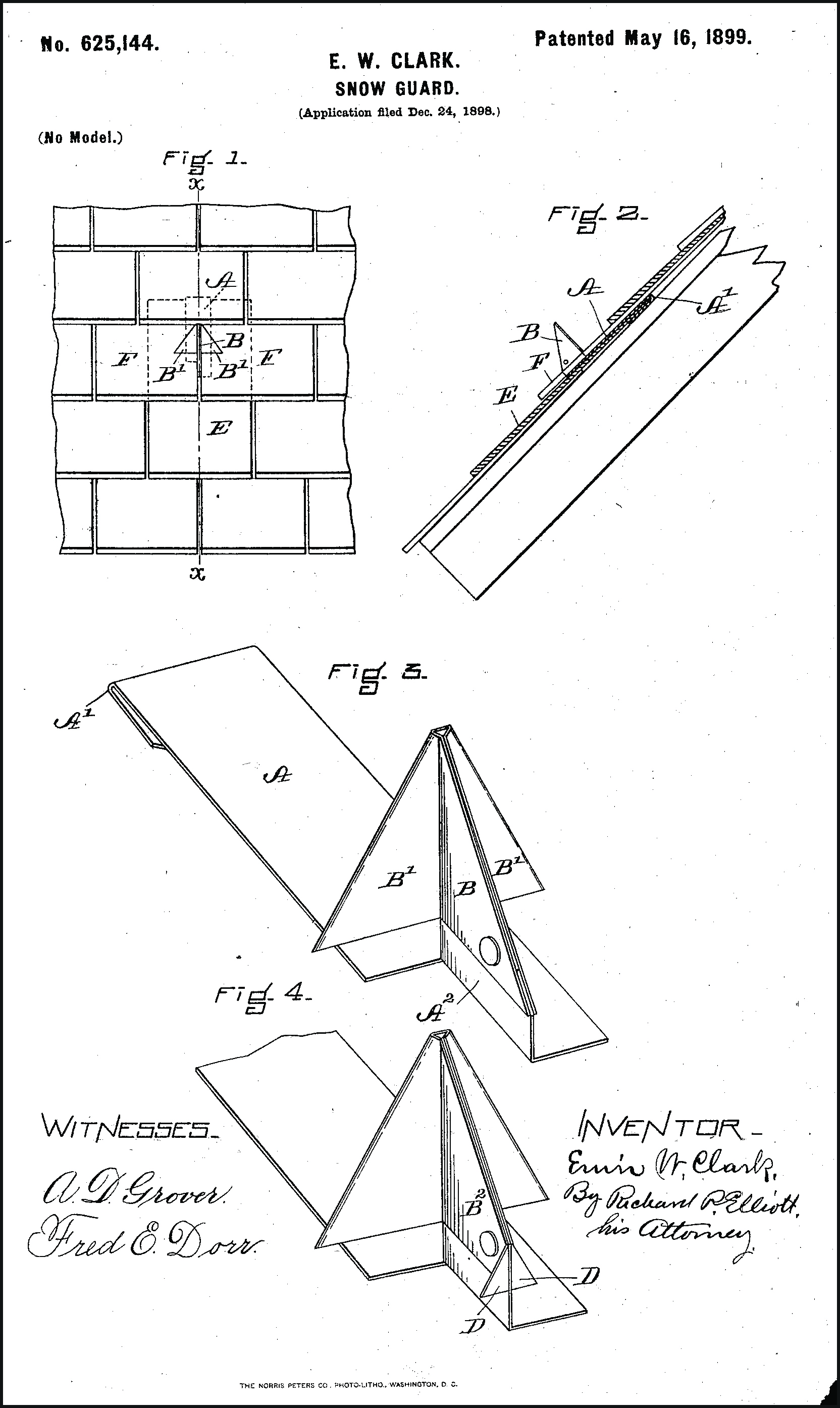

Over the years new snow guard patents have been awarded that simply copied, more than less, the Emri W. Clark patent of 1899 (#625144, below).

Then of course, from 1990 to today, the market has desperately, and without remorse, copied the Dixon technology of patent #1330309 (below) from 1920.

The snow guard industry, like most others, didn’t see a lot in the way of patent activity during the 1940’s. This was due to the War Effort. The country had just crawled out from under the grip of the Great Depression. Europe was involved with a new threat of war. Pearl Harbor was bombed on December 7, 1941, thrusting the US into WWII. It must have been an incredibly difficult time.

People were being asked to save scrap metal, rubber, paper and even rags to contribute to the war effort. One of my staff member’s Grandmother was asked to contribute all of her enamel, metal mixing bowls and silverware, so it could be melted down to contribute to the effort.

Promoting the War Effort was on the top of everyone’s mind, and citizen contributions were in full force. Providing supplies to American and Allied troops fighting the war in Europe, Africa and the Pacific was going to require the efforts of all Americans.

Back at home, citizens contributed to the effort by rationing goods, purchasing war bonds, recycling materials. Women began working in factories to replace the men who had been sent overseas (think Rosie the Riveter). Scrap iron drives were held, as were paper and rubber drives.

Victory Gardens, also known as war or food gardens for defense, were comprised of vegetable, fruit, and herb gardens planted at private homes and public parks across the United States, United Kingdom, Canada, Australia and even Germany during World War II (this was also true during WWI).

Clubs and civic organization were formed, including the Citizens Defense Corps. The Citizens Service Corps, American Unity, Salvage Program, and the above-mentioned Victory Gardens. The widespread messaging was that there was a job for every American through civil defense efforts.

Gasoline, clothes and meats were tightly rationed and most US families were allocated just 3 gallons of gas per week, which obviously put a near-stop to drive for any purpose. Even school-age children we’re expected to help on farms, oftentimes right in their schools very own Victory Garden. Teenagers filled in, which led to many states changing their child-labor laws in order to allow the teenagers to work.

Yet in the midst of it all, the Pentagon was built. It was, and still is, the largest office building in the world (6,500,000 sq. ft). To my knowledge it has the largest slate roof of any building in the US. It’s amazing to me that during a time when every able-bodied man enlisted in the military, we as a country were able to build such an enormous, magnificent structure in just over two years (closer to 16 months actually). It’s just as amazing that the slate for this roof could be produced, delivered and installed with such a limited work force. Ironically, groundbreaking for the construction of the Pentagon commenced on September 11th (1941).

In early 2000 I was asked to take a look at the slate roof and provide some feedback related to a long-term maintenance plan. To be fair, it’s my understanding that a roof consulting firm was engaged to manage all aspects of the roof maintenance. My involvement came as a result of writing The Slate Book. I was invited to share knowledge and give a general overview. Some interesting observations came as a result of that visit (stay tuned, a future blog will cover this). It’s fair to point out that the roof had been well maintained, was, and is, providing great service even though part of it had to be reroofed after the events of 9/11.

As an aside, the NRCA (National Roofing Contractors Association), without hesitation and (in my opinion) without recognition, jumped in and took charge of the reroofing of the Pentagon after 9/11. I personally don’t know all of the details as to who did what or when nor do I have specific knowledge about the project. If there’s a writer who possesses this knowledge, I’m confident that the readership here would love to know the specifics. At a minimum, I would like to express my gratitude to all who contributed.

Coming up next: The 1950’s. Snow guard were pretty dull during that era but construction (and babies) boomed post WWII. It was an exciting era for all aspects of construction…. except snow guards.

Until then….

Brian Stearns

President & Founder, Alpine SnowGuards

We keep snow in its place

888.766.4273

Sign up to start using our Online Project Calculator for an immediate layout and project pricing!

Subscribe to our monthly newsletter and keep up on the latest industry and Alpine news, products, and upcoming events!

Alpine SnowGuards designs, engineers, and manufactures snow management systems from our facilities in Morrisville, VT. We work closely with leading roofing contractors, engineering firms, developers, and roofing manufacturers to ensure we deliver quality products that do what we say they’ll do. Alpine SnowGuards can help a building qualify for LEED® credits.

(Images from: USPTO, Cleveland.com, the Edwardsville Intelligencer, Wikimedia Commons)