In my last blog, we looked into the evolution of snow guards through the history of roofing. This time, we’re taking a giant leap backwards, into the 90’s….The 1890’s!

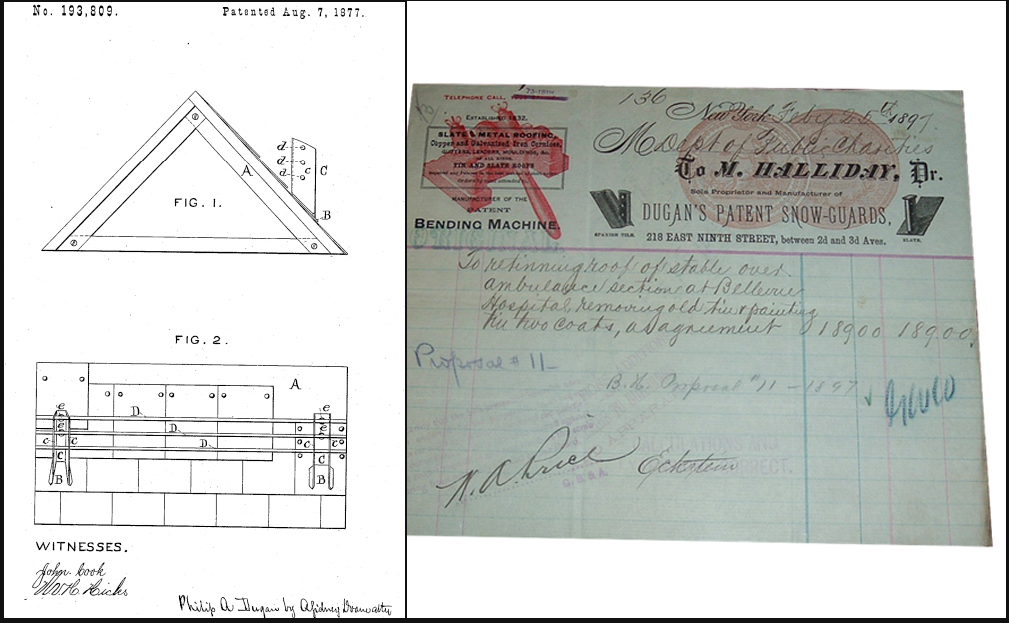

Below is a patent for snow guards that were made in the late 1800’s, a pipe-style system made and sold as Dugan’s Patent Snow-Guards. The date on the original patent is August 7, 1877 and the letterhead is dated 1897. Interestingly, the letterhead shows a pipe-style snow guard available to be used with Spanish tile and one for use with slate.

The address for the roofing contractor for this project is New York City. The invoice itself describes work to be done or being done at Bellevue Hospital in Manhattan (founded in 1736, it’s the oldest public hospital in the country). It isn’t clear if snow guard installation was a part of this project. What is clear is that the contractor was working on large scale commercial and / or institutional projects in NYC.

The letterhead is significant as it relates to a product the contractor believed in strongly enough to have patented and promoted. It may be a stretch for the reader, but I believe that contractors installing snow guards in the high traffic, cityscape of the late 1800’s understood that the appropriate snow guard for that environment was a pipe-style system.

You’ll notice that no slate or tile size is called out. Slate sizes vary. They can be one length and width for a project or they can be random widths and graduated lengths. It’s likely that these snow guards were made to order. Additionally, there were several clay tile manufacturers in this time period. The size of the Spanish tile would be driven by the tile manufacturer. In this case, the tile base was cast. Either the roofer had several molds he would use to make specific brands of Spanish tile, or he may have just made the one that was most readily available to him.

One additional note relates to the pipe stanchion on each of these brackets. The stanchions, as shown, are fixed in place – likely welded. I believe these brackets were fabricated to match the roof pitch of the given project. The common practice for pipe-style snow guard brackets during the era was to set the pipe orientation perpendicular to the ground. The point to note here is that 100 years later, in the 1990’s, it became common practice to set the pipe stanchion bracket orientation perpendicular to the roof surface.

Another, below, is a patent from 1899 filed by E.W. Clark. This is a pad-style snow guard. There are all sorts of things going on with this pad design:

- The pad is fabricated from sheet metal

- It has a hook on the upslope end of the sheet metal strap that allows the installer to hook it over the top of a piece of slate

- The stem portion that supports the snow pad slides between the vertical joint created by two adjoining pieces of slate

- The pad itself attaches to the stem at the center of the pad

- The sheet metal attachment strap is a fixed length that doesn’t vary

- The inventor realized the need to spread out compressive loads over a larger surface bearing area. By doing this, he reduced point loads on the slate that he talks about in his patent as known to cause slate fractures

This was a very good start to a sheet metal designed snow guard. Years later in the 1960’s and 1970’s, several other manufacturers set out to improve on this design. However, the design has some limitations that needed to be addressed later in the creative process.

Clark’s design was originally created exclusively for slate roof installations. The length of the strap works on any length slate as long as it’s installed with a 3” head-lap. This means that it can only be installed between the vertical joints in the slate – it’ll only work with standard thickness slate (1/4” thick was the standard for the era, as shown on this roof that was installed in 1885). Anything thicker would have prevented the triangular snow tabs from sliding over the adjacent slate.

Functionally, this part is intended to engage snow loads that are parallel to the roof slope. Interestingly, even from the 1960’s to the 1990’s, installers continued to make the mistake of installing snow guards that were parallel to the ground. I’m guessing because they were all essentially copying each other. An important aspect to take into account is that snow and ice accumulate heavily in valleys. Pad-style snow guards that are loaded with a mass moving in a valley are not loaded parallel to the roof slope. Instead they are loaded at the angle that the valley dictates. When this happens the triangular snow pads twist to match the angle of the load path (makes sense). As that happens, the sheet metal stem of the snow guards lays over on its side.

This was a solid attempt at making a sheet metal snow guard back in 1899. It was good enough that later inventors essentially knocked it off. Unfortunately, this design only worked on slate of one thickness, one width (in order to have a symmetrical layout) and on roofs with no valleys or roof anomalies causing the snow guards to be loaded at odd angles.

As a former slate roofing contractor, I can tell you that in the 1980’s-2000’s, I saw 3 or 4 such roofs. I repaired roofs that incorporated one of the later knock-offs and recognized the design limitations immediately. It was a good idea back in 1899, when slate roofs were more uniform. It would have very limited use with today’s varying shingle designs and sizes.

So, how did the roofing industry change and grow in years to come? Next time we’ll travel to the turn of the 20th century and the evolvement of snow guard designs.

Until then….

Brian Stearns

President & Founder, Alpine SnowGuards

We keep snow in its place

888.766.4273

Sign up to start using our Online Project Calculator for an immediate layout and project pricing!

Subscribe to our monthly newsletter and keep up on the latest industry and Alpine news, products, and upcoming events!

Alpine SnowGuards designs, engineers, and manufactures snow management systems from our facilities in Morrisville, VT. We work closely with leading roofing contractors, engineering firms, developers, and roofing manufacturers to ensure we deliver quality products that do what we say they’ll do. Alpine SnowGuards can help a building qualify for LEED® credits.

(Images from: USPTO, W.B. Morrison and the Alpine SnowGuards archives)